Product Description

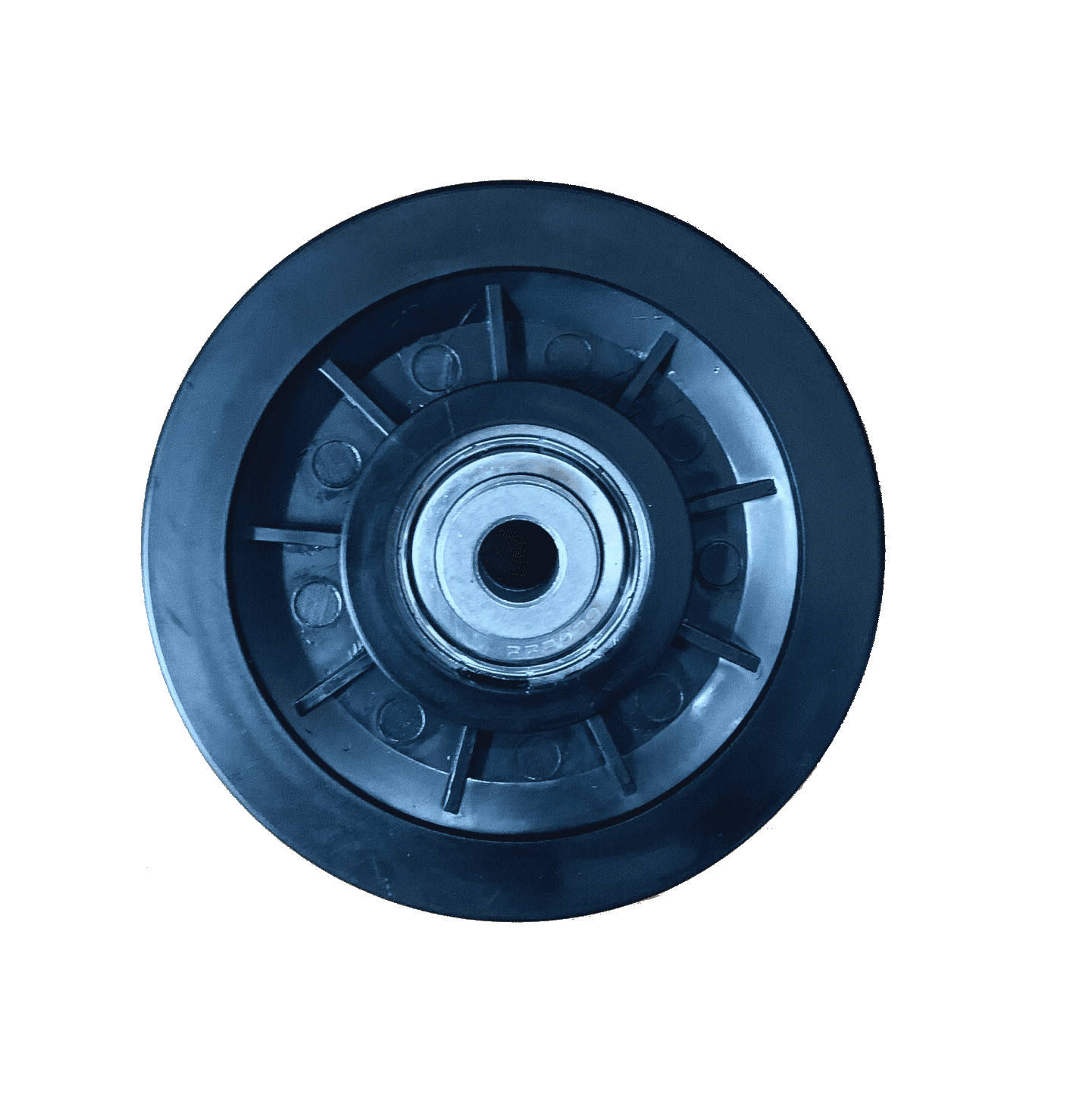

Adjustable 5cm Motor Pulley Gym Machine Power Steering Industrial Garage Door Nylon Dual Oversized Elevator Stainless Steel Wheel System Training Pulley

Application of Motor Pulley

Motor pulleys, also known as drive pulleys, are used with electric motors to transmit power and control the speed of driven systems. Here are some common applications of motor pulleys:

1. Belt-Driven Systems: Motor pulleys are often employed in belt-driven systems where power needs to be transmitted between the motor and driven machinery. They are used in CHINAMFG systems, industrial machinery, and conveyor systems.

2. CHINAMFG Systems: Motor pulleys are utilized in heating, ventilation, and air conditioning (HVAC) systems to drive the blower fans and other components. By connecting the motor to the fan using a belt and motor pulley, the rotational motion of the motor is transferred to the fan, enabling air circulation.

3. Industrial Machinery: Motor pulleys find application in various industrial machinery and equipment, including pumps, compressors, and manufacturing equipment. They transmit power from the motor to the driven components, allowing for the operation of different processes and tasks.

4. Agricultural Equipment: Motor pulleys are used in agricultural machinery, such as irrigation pumps, grain drills, and feed mixers. They transfer power from the motor to the equipment, enabling efficient operation and productivity in farming and agricultural applications.

5. Garage Door Openers: Motor pulleys are essential for garage door opener systems. They connect the motor to the drive mechanism, allowing the motor to open and close the garage door smoothly and reliably.

6. Exercise Equipment: Motor pulleys are employed in various types of exercise equipment, including treadmills, stationary bikes, and elliptical trainers. They transmit power from the motor to the exercise components, enabling the user to perform workouts with adjustable speed and resistance.

7. Manufacturing and Assembly Lines: Motor pulleys are used in manufacturing and assembly lines to drive conveyor belts and transfer systems. They facilitate the movement of materials, products, and components along the production line, ensuring efficient workflow and automation.

8. Automotive Accessories: Motor pulleys are utilized in automotive applications for driving various accessories, such as power steering pumps, alternators, and air conditioning compressors. They transmit power from the engine to these components, enabling their operation.

9. Printing Presses: Motor pulleys are employed in printing presses to drive rollers and other components that facilitate the printing process. They ensure precise and controlled movement of paper or other materials, allowing for accurate and high-quality printing.

10. Woodworking Machinery: Motor pulleys find application in woodworking machinery, such as table saws, band saws, and planers. They transfer power from the motor to the cutting or shaping components, enabling the woodworking operations.

These are just a few examples of the applications of motor pulleys. Their role in transmitting power and controlling speed makes them essential components in numerous industries and systems where motor-driven equipment is used.

Related products

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Customization: |

Available

| Customized Request |

|---|

How do gym pulleys enhance the versatility and functionality of fitness equipment?

Gym pulleys play a crucial role in enhancing the versatility and functionality of fitness equipment. Here’s an explanation of how they contribute to these aspects:

1. Variable Resistance:

Gym pulleys provide variable resistance, allowing users to adjust the amount of weight or tension applied during exercises. By changing the attachment point or selecting different weight plates, users can modify the resistance to suit their strength level and training goals. This versatility enables individuals of different fitness levels to use the same equipment effectively.

2. Multi-Angle Movements:

Pulleys enable multi-angle movements by providing a wide range of exercise angles and directions. Users can perform exercises from different positions and angles, targeting specific muscle groups and engaging stabilizer muscles. This versatility helps individuals work on muscle imbalances, improve functional movements, and add variety to their workouts.

3. Isolation and Compound Exercises:

Gym pulleys allow for both isolation and compound exercises. Isolation exercises target specific muscles by isolating their movement, while compound exercises involve multiple muscle groups working together. By adjusting the pulley attachment point and selecting the appropriate exercises, users can switch between isolation and compound movements, effectively targeting different muscle groups and achieving a well-rounded workout.

4. Freedom of Movement:

Pulleys provide a greater freedom of movement compared to traditional weightlifting equipment. The cables and pulleys allow users to perform exercises in various planes of motion, simulating real-life movements and sports-specific actions. This freedom of movement enhances functional training, improves range of motion, and helps prevent muscle imbalances.

5. Exercise Variety:

Gym pulleys offer a wide range of exercise options and variations. Users can perform exercises such as cable curls, tricep pushdowns, lat pulldowns, cable flyes, rows, and many more. By changing the cable attachments, adjusting the pulley height, or using different handles, individuals can target different muscle groups and achieve a diverse and challenging workout.

6. Rehabilitation and Physical Therapy:

Pulleys are often used in rehabilitation and physical therapy settings. The adjustable resistance and freedom of movement provided by pulley systems allow for controlled and progressive rehabilitation exercises. They can assist in strengthening injured or weakened muscles, improving joint mobility, and supporting the recovery process.

In summary, gym pulleys enhance the versatility and functionality of fitness equipment by providing variable resistance, enabling multi-angle movements, allowing for isolation and compound exercises, offering a greater freedom of movement, providing exercise variety, and facilitating rehabilitation and physical therapy. The incorporation of pulley systems into fitness equipment expands the range of exercises, targets specific muscle groups, accommodates various fitness levels, and promotes overall effectiveness in achieving fitness goals.

How does the quality and precision of gym pulleys impact workout effectiveness?

The quality and precision of gym pulleys have a significant impact on workout effectiveness. Here are the ways in which they influence the effectiveness of a workout:

1. Smooth and Consistent Resistance:

High-quality gym pulleys offer smooth and consistent resistance throughout the entire range of motion. This ensures that the resistance remains constant, allowing users to target specific muscle groups effectively. Smooth resistance also reduces the risk of jerky movements or muscle strain during exercises.

2. Accurate Weight Stack Measurements:

Precise weight stack measurements are essential for workout accuracy. Lower-quality pulley systems may have weight stacks that are not calibrated accurately, resulting in inconsistent resistance levels. Inaccurate weight measurements can hinder progress and make it challenging to track and progressively overload the muscles.

3. Durability and Longevity:

A high-quality pulley system is built to withstand heavy use and last for a long time. Quality materials and construction ensure that the pulley system can handle the demands of intense workouts without breaking down or experiencing premature wear. A durable pulley system provides a reliable and consistent training experience over an extended period.

4. Reduced Maintenance and Repairs:

Investing in a high-quality gym pulley system can help reduce the frequency of maintenance and repairs. Quality pulleys are designed with precision and built to withstand regular use, minimizing the need for frequent adjustments or part replacements. This allows users to focus more on their workouts and spend less time on maintenance tasks.

5. Noise Reduction:

Poorly constructed or low-quality pulley systems can produce excessive noise during operation. This can be distracting and disrupt the workout environment. High-quality pulleys are designed to operate smoothly and silently, providing a quieter and more enjoyable workout experience.

6. Safety and Stability:

A high-quality pulley system ensures safety and stability during exercises. Precise engineering and sturdy construction prevent unexpected movements, wobbling, or instability that could lead to accidents or injuries. Users can perform exercises with confidence, knowing that the pulley system provides a secure and stable platform for their workouts.

7. Ergonomics and Comfort:

Quality pulley systems are designed with user comfort and ergonomics in mind. Handles, grips, and attachments are often ergonomically shaped and padded to provide a comfortable and secure grip during exercises. This enhances the overall workout experience and allows users to focus on proper form and muscle engagement.

8. Confidence and Motivation:

Using a high-quality pulley system can boost confidence and motivation during workouts. When the equipment functions smoothly and reliably, users feel more confident in their exercises and are motivated to push themselves further. On the other hand, a low-quality or imprecise pulley system may lead to frustration and demotivation.

Investing in a quality gym pulley system with precise engineering, accurate weight measurements, durability, reduced maintenance needs, noise reduction, safety, ergonomics, and comfort can significantly enhance the effectiveness of workouts. A high-quality pulley system provides the necessary tools and support for individuals to achieve their fitness goals efficiently and safely.

How does the design of gym pulleys impact the smoothness and durability of workouts?

The design of gym pulleys plays a crucial role in ensuring smoothness and durability during workouts. Here’s an explanation of how the design of gym pulleys impacts these factors:

1. Bearing System:

The bearing system used in gym pulleys greatly influences smoothness. High-quality bearings, such as sealed ball bearings or roller bearings, minimize friction and enable the pulleys to rotate smoothly. Smooth rotation reduces any jerky or uneven movements during exercises, allowing for a more fluid and comfortable workout experience.

2. Pulley Size and Shape:

The size and shape of the pulleys impact the mechanical advantage and movement efficiency. Larger pulleys with a larger radius provide a mechanical advantage, reducing the force required to move the weight stack or resistance. Additionally, pulleys with a rounded or curved shape minimize friction and reduce wear on cables, enhancing durability and smoothness.

3. Cable Routing and Alignment:

The proper routing and alignment of cables within the pulley system are essential for smooth and efficient operation. Well-designed gym pulleys have cable guides or channels that ensure the cables follow a direct and consistent path, minimizing friction and preventing cable interference. Proper cable alignment also reduces wear and tear on the cables, enhancing durability.

4. Cable Quality:

The quality of the cables used in gym pulleys can significantly impact smoothness and durability. High-quality cables are typically constructed with strong materials, such as steel or nylon, and have a smooth coating to reduce friction. These cables provide smooth and consistent resistance, ensuring a more fluid and effective workout. Additionally, durable cables resist stretching or fraying, contributing to the longevity of the pulley system.

5. Frame and Construction:

The overall frame and construction of the gym pulley system influence its durability. A robust and well-engineered frame provides stability and support for the pulleys, preventing excessive vibrations or movement during workouts. The use of high-quality materials, reliable welds, and sturdy connections ensures the pulley system can withstand the stresses of regular use without compromising performance or safety.

6. Pulley Attachment Points:

The number and placement of pulley attachment points contribute to exercise versatility and smoothness. Well-designed gym pulleys offer multiple attachment points, allowing users to perform exercises from various angles and positions. This versatility ensures a more natural range of motion and minimizes any restrictions or awkward movements that could affect smoothness.

7. Maintenance and Lubrication:

The design of gym pulleys may incorporate features that facilitate maintenance and lubrication. Easy access to pulleys for cleaning and lubrication helps maintain smooth operation and prolongs the lifespan of the pulley system. Well-designed pulleys may include sealed bearings or self-lubricating bushings that reduce the need for frequent maintenance.

In summary, the design of gym pulleys impacts the smoothness and durability of workouts through factors such as the bearing system, pulley size and shape, cable routing and alignment, cable quality, frame and construction, pulley attachment points, and maintenance considerations. By optimizing these design aspects, manufacturers can create gym pulleys that provide a smooth and reliable workout experience, minimizing friction, maximizing efficiency, and ensuring long-lasting durability.

editor by CX

2024-05-17