Product Description

Product Description

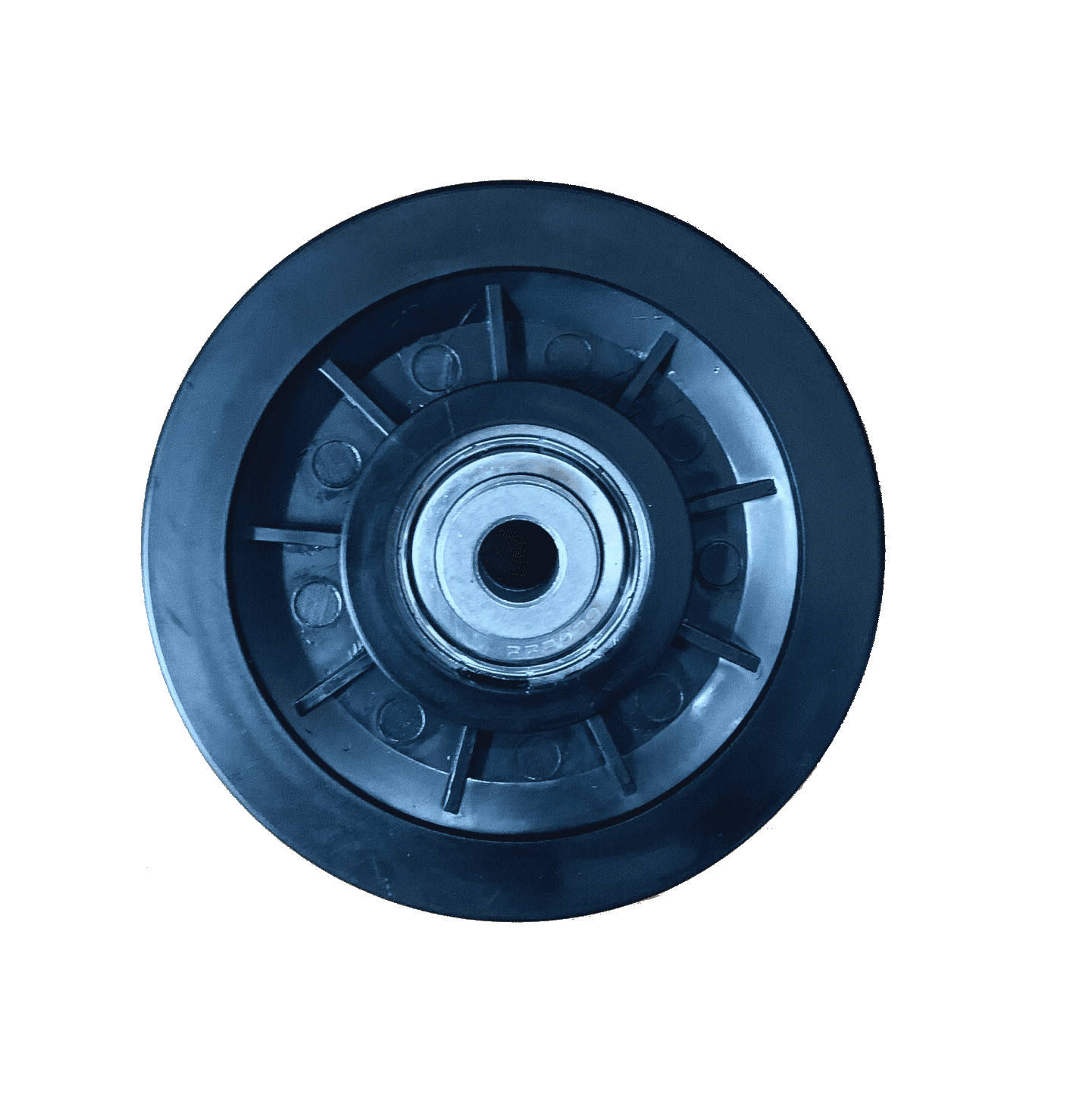

ITEM NO.: FM-1002

ITEM NAME: DUAL ADJUSTABLE PULLEY

SET UP DIMENSION: 1108*1050*2475mm

N.W. / G.W.: 218kg / 258kg

WEIGHT STACK: 360lbs / 162kg

Packaging & Shipping

Upgrade the packaging to high quality paper box, which looks more elegant and saves a lot of space.

Showroom & Trade show Pic

FAQ

Q1:How long about the lead time?

A1:Within 45 Days.

Q2:What is the Mini Quqntity?

A2:1 set both for strength equipment cardio machine (treadmill or exercise bike will be ok ).

Q3:Do you have some certification?

A3:Yes,we have passed CE,ISO9001.

Q4:How about the payment?

A4:We support the T/T ,L/C(50% deposit,50% balances before the shipment )

Q5:How about your after-service?

A5:We’ll send you the component for free to replace the damaged 1 during the warranty period.

Q6:Could you give me a scheme about the gym club?

A6:Yes,we can give you a precise project, a best design for free according to the square and your idea.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Gym Fitness Equipment |

|---|---|

| Exercise Part: | Chest |

| Application: | Gymnasium |

| Age: | Adult |

| Gender: | Men |

| Certification: | ISO |

| Customization: |

Available

| Customized Request |

|---|

How do gym pulleys ensure that resistance levels are consistent throughout exercises?

Gym pulleys are designed with specific mechanisms and features to ensure consistent resistance levels throughout exercises. Here’s an explanation of how gym pulleys achieve this:

1. Weight Stack System:

Gym pulley systems often employ a weight stack system, where weights are stacked on top of each other. Each weight plate has a designated value, usually marked in increments, such as pounds or kilograms. By selecting the desired weight plates, users can adjust the resistance level according to their preference or exercise requirements. The weight stack system ensures consistent resistance as the user moves the cable and engages with the pulley system.

2. Cable and Pulley Ratios:

Gym pulleys utilize specific cable and pulley ratios to maintain consistent resistance throughout exercises. The size and arrangement of the pulley wheels, along with the diameter and length of the cables, are carefully determined to achieve the desired resistance levels. The mechanical advantage provided by the pulley system ensures that the chosen weight plates translate into consistent resistance throughout the range of motion.

3. Friction and Tension Control:

Pulley systems incorporate mechanisms to control friction and tension, contributing to consistent resistance. Tension adjustment mechanisms, such as weight selectors or cable tensioners, allow users to fine-tune the tension of the cables to match their desired resistance level. Additionally, pulley wheels may feature materials or coatings that reduce friction, ensuring smooth and consistent resistance during exercises.

4. Cable Attachment Points:

Gym pulleys provide multiple attachment points for cables, allowing users to vary the resistance and exercise angles. By attaching the cables to different points on the pulley system, users can modify the mechanical advantage and resistance experienced during exercises. This versatility ensures consistent resistance levels across different movements and workout variations.

5. Maintenance and Calibration:

Regular maintenance and calibration of gym pulley systems are essential for ensuring consistent resistance levels. This involves inspecting and adjusting the cable tension, confirming the alignment of pulley wheels, and verifying the accuracy of weight plates. Proper maintenance and calibration help maintain the integrity of the pulley system, ensuring the resistance levels remain consistent over time.

In summary, gym pulleys ensure consistent resistance levels throughout exercises through the use of weight stack systems, cable and pulley ratios, friction and tension control mechanisms, multiple cable attachment points, and regular maintenance and calibration. By employing these design elements and features, gym pulley systems provide users with reliable and consistent resistance, allowing for effective and accurate workouts.

How does the quality and precision of gym pulleys impact workout effectiveness?

The quality and precision of gym pulleys have a significant impact on workout effectiveness. Here are the ways in which they influence the effectiveness of a workout:

1. Smooth and Consistent Resistance:

High-quality gym pulleys offer smooth and consistent resistance throughout the entire range of motion. This ensures that the resistance remains constant, allowing users to target specific muscle groups effectively. Smooth resistance also reduces the risk of jerky movements or muscle strain during exercises.

2. Accurate Weight Stack Measurements:

Precise weight stack measurements are essential for workout accuracy. Lower-quality pulley systems may have weight stacks that are not calibrated accurately, resulting in inconsistent resistance levels. Inaccurate weight measurements can hinder progress and make it challenging to track and progressively overload the muscles.

3. Durability and Longevity:

A high-quality pulley system is built to withstand heavy use and last for a long time. Quality materials and construction ensure that the pulley system can handle the demands of intense workouts without breaking down or experiencing premature wear. A durable pulley system provides a reliable and consistent training experience over an extended period.

4. Reduced Maintenance and Repairs:

Investing in a high-quality gym pulley system can help reduce the frequency of maintenance and repairs. Quality pulleys are designed with precision and built to withstand regular use, minimizing the need for frequent adjustments or part replacements. This allows users to focus more on their workouts and spend less time on maintenance tasks.

5. Noise Reduction:

Poorly constructed or low-quality pulley systems can produce excessive noise during operation. This can be distracting and disrupt the workout environment. High-quality pulleys are designed to operate smoothly and silently, providing a quieter and more enjoyable workout experience.

6. Safety and Stability:

A high-quality pulley system ensures safety and stability during exercises. Precise engineering and sturdy construction prevent unexpected movements, wobbling, or instability that could lead to accidents or injuries. Users can perform exercises with confidence, knowing that the pulley system provides a secure and stable platform for their workouts.

7. Ergonomics and Comfort:

Quality pulley systems are designed with user comfort and ergonomics in mind. Handles, grips, and attachments are often ergonomically shaped and padded to provide a comfortable and secure grip during exercises. This enhances the overall workout experience and allows users to focus on proper form and muscle engagement.

8. Confidence and Motivation:

Using a high-quality pulley system can boost confidence and motivation during workouts. When the equipment functions smoothly and reliably, users feel more confident in their exercises and are motivated to push themselves further. On the other hand, a low-quality or imprecise pulley system may lead to frustration and demotivation.

Investing in a quality gym pulley system with precise engineering, accurate weight measurements, durability, reduced maintenance needs, noise reduction, safety, ergonomics, and comfort can significantly enhance the effectiveness of workouts. A high-quality pulley system provides the necessary tools and support for individuals to achieve their fitness goals efficiently and safely.

What types of materials are typically used in the construction of gym pulleys?

Gym pulleys are constructed using a variety of materials that are chosen for their durability, strength, and smooth operation. Here are some commonly used materials in the construction of gym pulleys:

1. Metal:

Metal, such as steel or aluminum, is frequently used in the construction of gym pulleys. These metals offer excellent strength and durability, making them suitable for handling heavy loads and providing long-lasting performance. Steel is known for its robustness, while aluminum is valued for its lightweight nature.

2. Nylon:

Nylon is a popular material for gym pulley wheels or sheaves. It is chosen for its low friction properties, which allow for smooth and quiet operation. Nylon pulleys are resistant to wear and can withstand repetitive use without compromising performance. They are also lightweight and cost-effective.

3. UHMW (Ultra-High-Molecular-Weight Polyethylene):

UHMW polyethylene is a high-performance plastic material commonly used in gym pulleys. It has excellent strength, low friction coefficient, and high wear resistance. UHMW pulleys provide smooth rotation, reduce noise, and require minimal maintenance. They are also resistant to chemicals and impact, making them suitable for demanding gym environments.

4. Stainless Steel:

Stainless steel is utilized in gym pulleys for its corrosion resistance and durability. It is commonly used in pulley shafts, brackets, and other components that require high strength and resistance to moisture or sweat. Stainless steel pulleys maintain their performance and appearance over time, even in humid or corrosive environments.

5. Plastic Composites:

Plastic composites, such as reinforced polymers or fiberglass-reinforced plastics, are sometimes used in the construction of gym pulleys. These materials offer a balance between strength, weight, and cost. Plastic composite pulleys can provide durability and smooth operation while being lighter and more affordable compared to all-metal alternatives.

6. Bearings and Bushings:

In addition to the materials mentioned above, gym pulleys incorporate bearings or bushings to facilitate smooth rotation. Bearings, typically made of steel or ceramic, minimize friction and allow the pulleys to rotate freely. Bushings, often made of bronze or other self-lubricating materials, provide low-friction contact points for the rotating components.

It’s important to note that the specific materials used in gym pulleys can vary depending on the manufacturer, design, and intended use of the equipment. Manufacturers may employ a combination of materials to optimize performance, durability, and cost-effectiveness.

In summary, gym pulleys are commonly constructed using materials such as metal (steel or aluminum), nylon, UHMW polyethylene, stainless steel, plastic composites, as well as bearings and bushings. These materials offer a balance of strength, durability, low friction, and corrosion resistance, ensuring smooth operation and longevity of the gym pulley systems.

editor by CX

2024-05-17