Product Description

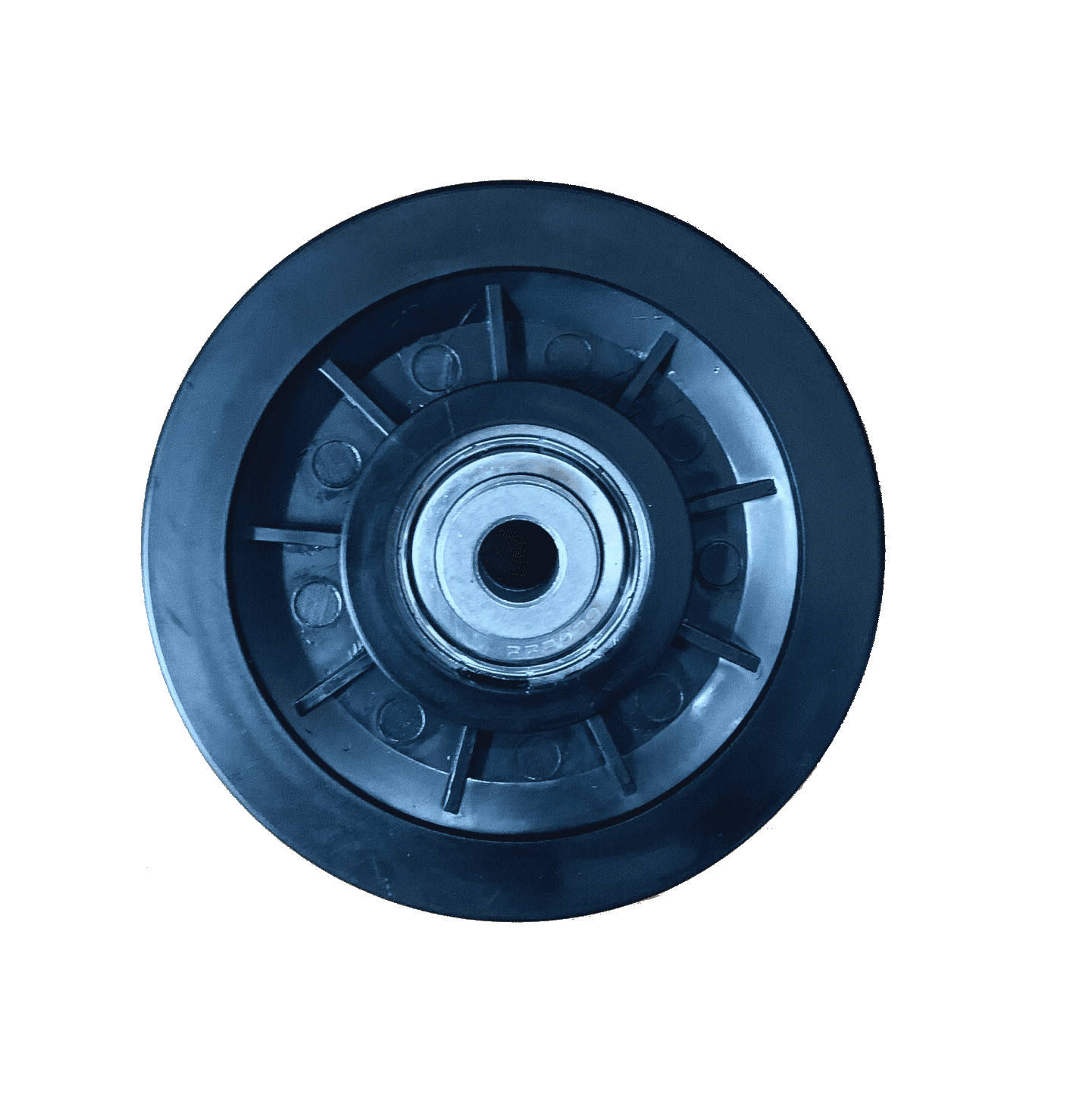

Adjustable 5cm Motor Pulley Gym Machine Power Steering Industrial Garage Door Nylon Dual Oversized Elevator Stainless Steel Wheel System Training Pulley

Application of Motor Pulley

Motor pulleys, also known as drive pulleys, are used with electric motors to transmit power and control the speed of driven systems. Here are some common applications of motor pulleys:

1. Belt-Driven Systems: Motor pulleys are often employed in belt-driven systems where power needs to be transmitted between the motor and driven machinery. They are used in CHINAMFG systems, industrial machinery, and conveyor systems.

2. CHINAMFG Systems: Motor pulleys are utilized in heating, ventilation, and air conditioning (HVAC) systems to drive the blower fans and other components. By connecting the motor to the fan using a belt and motor pulley, the rotational motion of the motor is transferred to the fan, enabling air circulation.

3. Industrial Machinery: Motor pulleys find application in various industrial machinery and equipment, including pumps, compressors, and manufacturing equipment. They transmit power from the motor to the driven components, allowing for the operation of different processes and tasks.

4. Agricultural Equipment: Motor pulleys are used in agricultural machinery, such as irrigation pumps, grain drills, and feed mixers. They transfer power from the motor to the equipment, enabling efficient operation and productivity in farming and agricultural applications.

5. Garage Door Openers: Motor pulleys are essential for garage door opener systems. They connect the motor to the drive mechanism, allowing the motor to open and close the garage door smoothly and reliably.

6. Exercise Equipment: Motor pulleys are employed in various types of exercise equipment, including treadmills, stationary bikes, and elliptical trainers. They transmit power from the motor to the exercise components, enabling the user to perform workouts with adjustable speed and resistance.

7. Manufacturing and Assembly Lines: Motor pulleys are used in manufacturing and assembly lines to drive conveyor belts and transfer systems. They facilitate the movement of materials, products, and components along the production line, ensuring efficient workflow and automation.

8. Automotive Accessories: Motor pulleys are utilized in automotive applications for driving various accessories, such as power steering pumps, alternators, and air conditioning compressors. They transmit power from the engine to these components, enabling their operation.

9. Printing Presses: Motor pulleys are employed in printing presses to drive rollers and other components that facilitate the printing process. They ensure precise and controlled movement of paper or other materials, allowing for accurate and high-quality printing.

10. Woodworking Machinery: Motor pulleys find application in woodworking machinery, such as table saws, band saws, and planers. They transfer power from the motor to the cutting or shaping components, enabling the woodworking operations.

These are just a few examples of the applications of motor pulleys. Their role in transmitting power and controlling speed makes them essential components in numerous industries and systems where motor-driven equipment is used.

Related products

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

Are there different types of gym pulleys, and how do they vary in fitness equipment?

Yes, there are different types of gym pulleys that vary in fitness equipment. Here’s an overview of the common types of gym pulleys and their variations:

1. Fixed Pulleys:

Fixed pulleys are stationary pulleys that are mounted to a fixed point or structure. They have a simple design with a grooved wheel that rotates on a fixed axle. Fixed pulleys change the direction of force, allowing users to pull or lift weights in a different direction. They are commonly used in cable machines and provide a consistent resistance throughout the exercise movement.

2. Adjustable Pulleys:

Adjustable pulleys are designed to change the height or position of the pulley attachment point. They typically feature a sliding mechanism or multiple attachment points along a vertical or horizontal track. By adjusting the attachment point, users can modify the mechanical advantage and resistance experienced during exercises. Adjustable pulleys offer versatility and allow for a wide range of exercise variations.

3. Cable Crossover Machines:

Cable crossover machines incorporate a combination of pulleys and cables to create a versatile and comprehensive workout station. These machines feature two or more pulley systems positioned on opposite ends, allowing users to perform various exercises targeting different muscle groups. Cable crossover machines often have adjustable pulleys, enabling users to customize the resistance and exercise angles.

4. Functional Trainers:

Functional trainers are multi-purpose fitness equipment that utilize pulley systems. They typically consist of two independent weight stacks and pulley systems on each side. Functional trainers offer a wide range of exercise possibilities, including traditional strength training exercises, functional movements, and rehabilitation exercises. The pulley systems in functional trainers are adjustable and allow users to target specific muscle groups from different angles.

5. Selectorized Machines:

Selectorized machines are weight-based fitness equipment that incorporate pulley systems. These machines feature a stack of weight plates with a selector pin that allows users to choose the desired weight. The weight stack is connected to a pulley system, enabling users to perform various exercises while adjusting the resistance level easily. Selectorized machines often have multiple pulleys and cable attachment points to provide exercise versatility.

6. Smith Machines:

Smith machines are a type of weightlifting equipment that include a barbell attached to a guided vertical track. The barbell moves along the track with the help of pulleys, allowing for controlled and safer weightlifting exercises. Smith machines often incorporate pulley systems for additional cable-based exercises, providing more workout options.

In summary, gym pulleys vary in fitness equipment and include fixed pulleys, adjustable pulleys, cable crossover machines, functional trainers, selectorized machines, and pulley systems in Smith machines. Each type of pulley offers specific features and functionality, providing users with different exercise options and resistance variations.

What safety considerations should be kept in mind when using gym pulley machines?

When using gym pulley machines, it’s important to prioritize safety to prevent injuries and ensure a safe workout environment. Here are some key safety considerations to keep in mind:

1. Proper Technique and Form:

Learn and practice proper technique and form for each exercise. Incorrect form can increase the risk of injury. If you’re unsure about the correct technique, seek guidance from a qualified fitness professional or trainer.

2. Warm-Up and Cool-Down:

Always warm up before starting your workout session. A proper warm-up prepares your muscles and joints for exercise, reducing the risk of strains or sprains. Similarly, cool down and stretch after your workout to promote recovery and flexibility.

3. Use Appropriate Resistance:

Select an appropriate resistance level that matches your fitness level and goals. Starting with excessive resistance can lead to poor form and potential injuries. Gradually increase the resistance as your strength improves.

4. Adjust the Equipment:

Ensure that the pulley machine is properly adjusted to your body size and range of motion. Adjust the seat height, cable attachment points, and handles to maintain proper alignment and comfortable positioning during exercises.

5. Maintain Control and Stability:

Always maintain control and stability during exercises. Avoid sudden jerky movements or swinging motions that can strain your muscles or cause accidents. Focus on smooth, controlled movements throughout the entire range of motion.

6. Use Safety Features:

Make use of any safety features provided with the pulley machine. These may include safety pins, weight stack locks, or emergency stop buttons. Familiarize yourself with these features and use them appropriately to ensure safe operation.

7. Wear Appropriate Attire:

Wear proper workout attire, including comfortable clothing and athletic shoes with good support. Avoid loose clothing or dangling accessories that can get caught in the pulley system.

8. Stay Hydrated:

Stay hydrated throughout your workout session. Proper hydration is essential for optimal performance and helps prevent muscle cramps or fatigue.

9. Listen to Your Body:

Pay attention to your body’s signals during exercise. If you experience pain, dizziness, or excessive fatigue, stop the exercise and seek medical attention if needed. Pushing through pain or discomfort can lead to injuries.

10. Maintain Equipment:

Regularly inspect the pulley machine for any signs of wear, damage, or malfunction. If you notice any issues, report them to the appropriate personnel or facility management. Follow the manufacturer’s guidelines for equipment maintenance and cleaning.

By following these safety considerations, you can minimize the risk of injuries and create a safe workout environment when using gym pulley machines.

What types of materials are typically used in the construction of gym pulleys?

Gym pulleys are constructed using a variety of materials that are chosen for their durability, strength, and smooth operation. Here are some commonly used materials in the construction of gym pulleys:

1. Metal:

Metal, such as steel or aluminum, is frequently used in the construction of gym pulleys. These metals offer excellent strength and durability, making them suitable for handling heavy loads and providing long-lasting performance. Steel is known for its robustness, while aluminum is valued for its lightweight nature.

2. Nylon:

Nylon is a popular material for gym pulley wheels or sheaves. It is chosen for its low friction properties, which allow for smooth and quiet operation. Nylon pulleys are resistant to wear and can withstand repetitive use without compromising performance. They are also lightweight and cost-effective.

3. UHMW (Ultra-High-Molecular-Weight Polyethylene):

UHMW polyethylene is a high-performance plastic material commonly used in gym pulleys. It has excellent strength, low friction coefficient, and high wear resistance. UHMW pulleys provide smooth rotation, reduce noise, and require minimal maintenance. They are also resistant to chemicals and impact, making them suitable for demanding gym environments.

4. Stainless Steel:

Stainless steel is utilized in gym pulleys for its corrosion resistance and durability. It is commonly used in pulley shafts, brackets, and other components that require high strength and resistance to moisture or sweat. Stainless steel pulleys maintain their performance and appearance over time, even in humid or corrosive environments.

5. Plastic Composites:

Plastic composites, such as reinforced polymers or fiberglass-reinforced plastics, are sometimes used in the construction of gym pulleys. These materials offer a balance between strength, weight, and cost. Plastic composite pulleys can provide durability and smooth operation while being lighter and more affordable compared to all-metal alternatives.

6. Bearings and Bushings:

In addition to the materials mentioned above, gym pulleys incorporate bearings or bushings to facilitate smooth rotation. Bearings, typically made of steel or ceramic, minimize friction and allow the pulleys to rotate freely. Bushings, often made of bronze or other self-lubricating materials, provide low-friction contact points for the rotating components.

It’s important to note that the specific materials used in gym pulleys can vary depending on the manufacturer, design, and intended use of the equipment. Manufacturers may employ a combination of materials to optimize performance, durability, and cost-effectiveness.

In summary, gym pulleys are commonly constructed using materials such as metal (steel or aluminum), nylon, UHMW polyethylene, stainless steel, plastic composites, as well as bearings and bushings. These materials offer a balance of strength, durability, low friction, and corrosion resistance, ensuring smooth operation and longevity of the gym pulley systems.

editor by CX

2024-04-11