Product Description

washing machine pulley mold system gym system gym motorized pulleys crankshaft toothed machine network cable wall mounted stainless steel

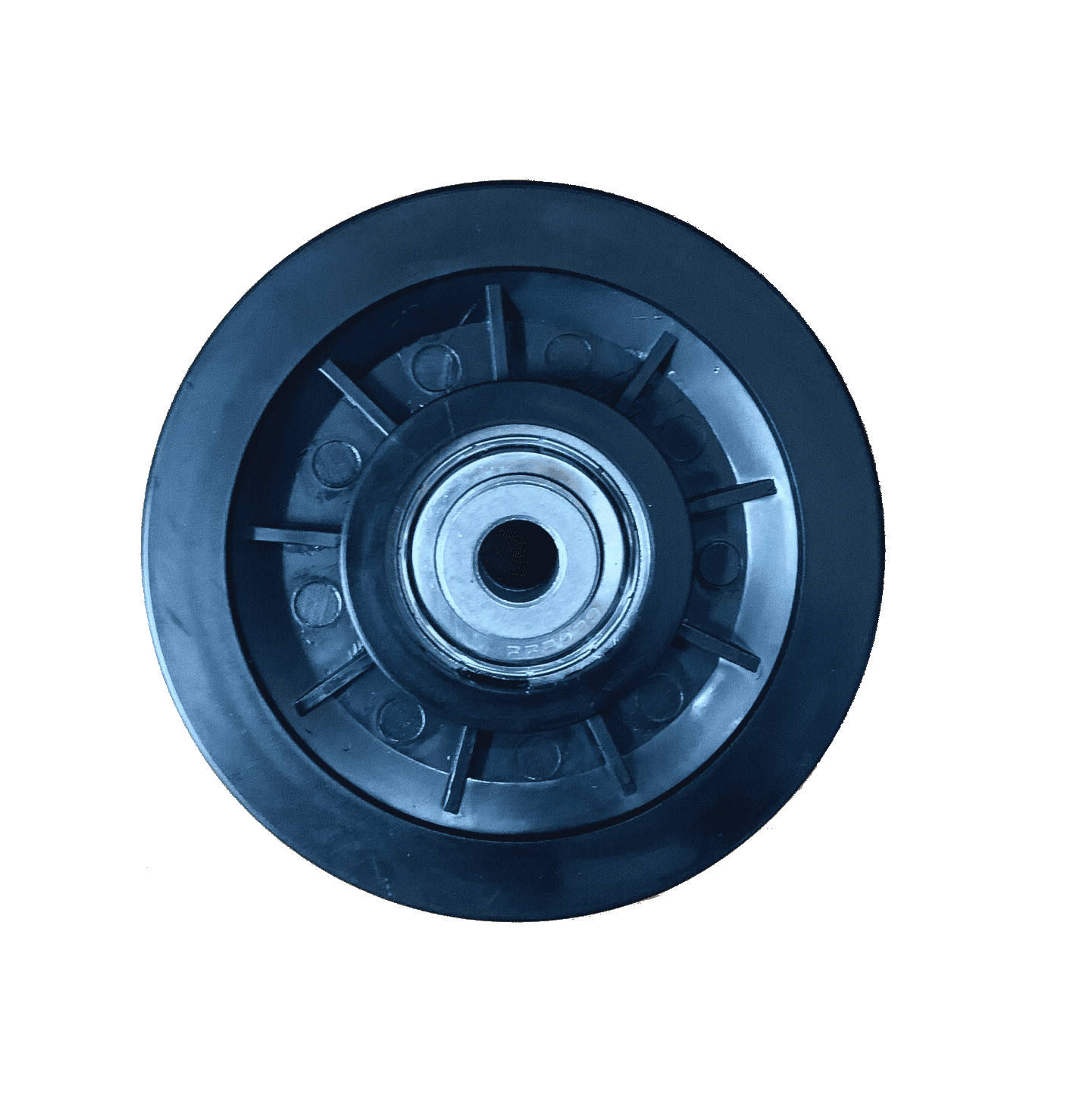

What is washing machine pulley?

A washing machine pulley is a wheel with a grooved rim that is attached to the motor of a washing machine. The belt that drives the drum of the washing machine wraps around the pulley. When the motor turns, the pulley turns, and the belt turns the drum. The pulley is an important part of the washing machine, and it helps to ensure that the drum turns smoothly and efficiently.

Washing machine pulleys can wear out over time, and they may need to be replaced if they become damaged or worn. If you notice that your washing machine is not spinning properly or if the belt is slipping, it is a good idea to check the pulley. If the pulley is damaged, it should be replaced immediately.

Here are some of the symptoms of a damaged washing machine pulley:

- The washing machine drum does not spin smoothly.

- The washing machine belt slips.

- The washing machine makes a loud noise when it is running.

- The washing machine leaks water.

If you notice any of these symptoms, it is important to have your washing machine checked by a qualified technician.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Are there different types of gym pulleys, and how do they vary in fitness equipment?

Yes, there are different types of gym pulleys that vary in fitness equipment. Here’s an overview of the common types of gym pulleys and their variations:

1. Fixed Pulleys:

Fixed pulleys are stationary pulleys that are mounted to a fixed point or structure. They have a simple design with a grooved wheel that rotates on a fixed axle. Fixed pulleys change the direction of force, allowing users to pull or lift weights in a different direction. They are commonly used in cable machines and provide a consistent resistance throughout the exercise movement.

2. Adjustable Pulleys:

Adjustable pulleys are designed to change the height or position of the pulley attachment point. They typically feature a sliding mechanism or multiple attachment points along a vertical or horizontal track. By adjusting the attachment point, users can modify the mechanical advantage and resistance experienced during exercises. Adjustable pulleys offer versatility and allow for a wide range of exercise variations.

3. Cable Crossover Machines:

Cable crossover machines incorporate a combination of pulleys and cables to create a versatile and comprehensive workout station. These machines feature two or more pulley systems positioned on opposite ends, allowing users to perform various exercises targeting different muscle groups. Cable crossover machines often have adjustable pulleys, enabling users to customize the resistance and exercise angles.

4. Functional Trainers:

Functional trainers are multi-purpose fitness equipment that utilize pulley systems. They typically consist of two independent weight stacks and pulley systems on each side. Functional trainers offer a wide range of exercise possibilities, including traditional strength training exercises, functional movements, and rehabilitation exercises. The pulley systems in functional trainers are adjustable and allow users to target specific muscle groups from different angles.

5. Selectorized Machines:

Selectorized machines are weight-based fitness equipment that incorporate pulley systems. These machines feature a stack of weight plates with a selector pin that allows users to choose the desired weight. The weight stack is connected to a pulley system, enabling users to perform various exercises while adjusting the resistance level easily. Selectorized machines often have multiple pulleys and cable attachment points to provide exercise versatility.

6. Smith Machines:

Smith machines are a type of weightlifting equipment that include a barbell attached to a guided vertical track. The barbell moves along the track with the help of pulleys, allowing for controlled and safer weightlifting exercises. Smith machines often incorporate pulley systems for additional cable-based exercises, providing more workout options.

In summary, gym pulleys vary in fitness equipment and include fixed pulleys, adjustable pulleys, cable crossover machines, functional trainers, selectorized machines, and pulley systems in Smith machines. Each type of pulley offers specific features and functionality, providing users with different exercise options and resistance variations.

What is the importance of proper lubrication and maintenance in gym pulley systems?

Proper lubrication and maintenance are crucial for maintaining the performance, functionality, and longevity of gym pulley systems. Here’s why they are important:

1. Smooth Functioning:

Lubrication ensures smooth movement of the pulley system components, such as cables, pulleys, and bearings. It reduces friction and prevents excessive wear, allowing the system to operate efficiently. Smooth functioning enhances the user experience and promotes proper exercise execution.

2. Preventing Wear and Tear:

Regular maintenance, including lubrication, helps prevent wear and tear on the pulley system components. Over time, friction and use can cause parts to degrade or become damaged. Proper lubrication reduces friction, minimizes component wear, and extends the lifespan of the pulley system.

3. Noise Reduction:

Unlubricated pulley systems can generate squeaking or grinding noises during operation. These noises can be disruptive and distracting, affecting the overall workout environment. Lubrication reduces friction-related noise, promoting a quieter and more pleasant exercise experience.

4. Safety:

Maintaining a properly lubricated pulley system helps ensure user safety. Friction and inadequate lubrication can lead to jerky or uneven movements, potentially causing accidents or injuries. Lubrication keeps the system running smoothly, allowing users to perform exercises with controlled and predictable motions.

5. Performance and Efficiency:

A well-maintained pulley system contributes to optimal performance and exercise efficiency. Smooth operation allows users to focus on their workouts without interruptions or distractions. Proper lubrication also helps maintain the accuracy of resistance levels, ensuring consistent and effective training.

6. Preventing Corrosion and Rust:

In environments with high humidity or exposure to moisture, pulley system components, such as cables and metal parts, are susceptible to corrosion and rust. Regular maintenance, including lubrication, helps create a barrier against moisture and prevents corrosion, preserving the integrity of the pulley system.

7. Manufacturer’s Recommendations:

Proper lubrication and maintenance are often recommended by the pulley system manufacturers. Following their guidelines ensures that the system functions optimally and maintains the warranty coverage. Neglecting maintenance requirements may void the warranty or result in costly repairs.

8. Inspection and Repairs:

Regular maintenance, including lubrication, provides an opportunity to inspect the pulley system for any signs of damage, wear, or loose components. Early detection of issues allows for timely repairs or part replacements, preventing further damage and ensuring continued safe use.

It’s important to refer to the manufacturer’s instructions or consult with fitness equipment professionals for specific lubrication and maintenance guidelines for your gym pulley system. By prioritizing proper lubrication and maintenance, you can optimize the performance, safety, and longevity of your gym pulley system.

What types of materials are typically used in the construction of gym pulleys?

Gym pulleys are constructed using a variety of materials that are chosen for their durability, strength, and smooth operation. Here are some commonly used materials in the construction of gym pulleys:

1. Metal:

Metal, such as steel or aluminum, is frequently used in the construction of gym pulleys. These metals offer excellent strength and durability, making them suitable for handling heavy loads and providing long-lasting performance. Steel is known for its robustness, while aluminum is valued for its lightweight nature.

2. Nylon:

Nylon is a popular material for gym pulley wheels or sheaves. It is chosen for its low friction properties, which allow for smooth and quiet operation. Nylon pulleys are resistant to wear and can withstand repetitive use without compromising performance. They are also lightweight and cost-effective.

3. UHMW (Ultra-High-Molecular-Weight Polyethylene):

UHMW polyethylene is a high-performance plastic material commonly used in gym pulleys. It has excellent strength, low friction coefficient, and high wear resistance. UHMW pulleys provide smooth rotation, reduce noise, and require minimal maintenance. They are also resistant to chemicals and impact, making them suitable for demanding gym environments.

4. Stainless Steel:

Stainless steel is utilized in gym pulleys for its corrosion resistance and durability. It is commonly used in pulley shafts, brackets, and other components that require high strength and resistance to moisture or sweat. Stainless steel pulleys maintain their performance and appearance over time, even in humid or corrosive environments.

5. Plastic Composites:

Plastic composites, such as reinforced polymers or fiberglass-reinforced plastics, are sometimes used in the construction of gym pulleys. These materials offer a balance between strength, weight, and cost. Plastic composite pulleys can provide durability and smooth operation while being lighter and more affordable compared to all-metal alternatives.

6. Bearings and Bushings:

In addition to the materials mentioned above, gym pulleys incorporate bearings or bushings to facilitate smooth rotation. Bearings, typically made of steel or ceramic, minimize friction and allow the pulleys to rotate freely. Bushings, often made of bronze or other self-lubricating materials, provide low-friction contact points for the rotating components.

It’s important to note that the specific materials used in gym pulleys can vary depending on the manufacturer, design, and intended use of the equipment. Manufacturers may employ a combination of materials to optimize performance, durability, and cost-effectiveness.

In summary, gym pulleys are commonly constructed using materials such as metal (steel or aluminum), nylon, UHMW polyethylene, stainless steel, plastic composites, as well as bearings and bushings. These materials offer a balance of strength, durability, low friction, and corrosion resistance, ensuring smooth operation and longevity of the gym pulley systems.

editor by CX

2024-05-13