Product Description

OEM CHINAMFG wheel Pulley Steel Cast iron pulley

1. Product Details:

Material: steel, stainless steel, carbon steel,

Technology: precision casting

Surface treatment: sand blast, polishing, painting, powder coating

Machining: grinding, tapping, drilling, cnc

Application: engineering machinery parts, agricultural casting, construction equipment

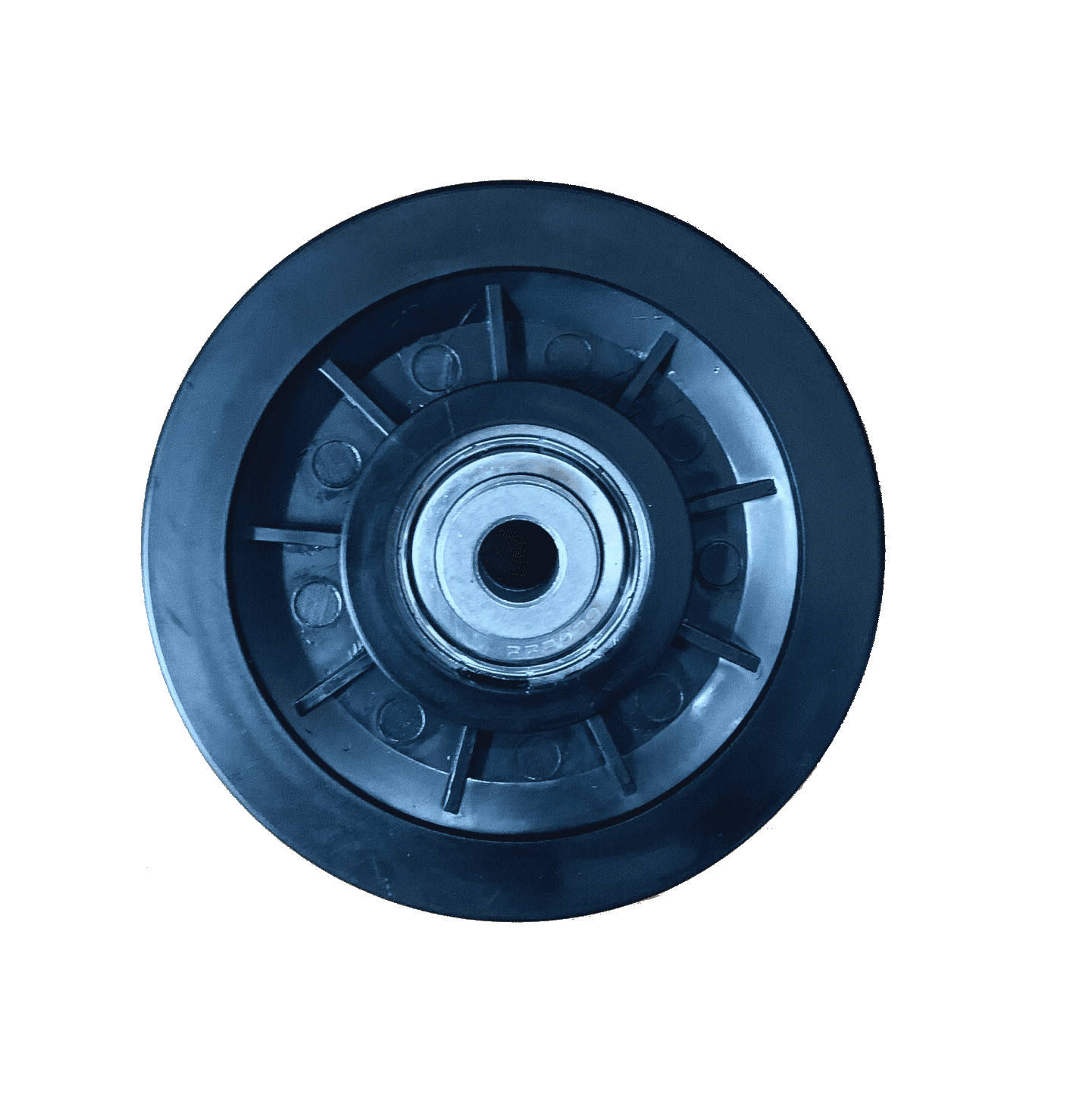

2. Product Pictures:

| Item | OEM Wheel Pulley Chain Pulley Block Gym Pulley |

| Technology | Precision casting, Investment casting, Lost wax casting |

| Investment casting | Lost wax casting and water glass casting |

| Material | Stainless steel and carbon steel |

| Machining | Tapping, grinding, drilling, threading, milling |

| Finish | Sand blasting, polishing, painting |

| Tolerance | +/-0.01mm |

| Application | Construction machinery parts, auto parts, industrial parts |

HangZhou Xihu (West Lake) Dis. Machinery Co.,Ltd.

FAQ

- 1. How can I get thequotation?

Please send us information for quote: drawing, material, weight, quantity and request.

- 2. If we don’t have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

- 3. When can I get thesample?

Sample: 25-30 days after you start to make mold. The accurate time depends on your product.

- 4. What is your main order time?

Order time: 35-40 days after the payment. The accurate time depends on your product.

- 5. What is yourpayment method?

Tooling: 100% TT advanced.

Main order: 50% deposit, balance 50% to be paid before shipment.

- 6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..

- 7. If you export to our country before, can I get the information of your import customer in our country?

We can’t offer you all the information of our customer because we have duty to protect our customers’ privacy. But we can provide you some part of B/L.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE |

|---|---|

| Pulley Sizes: | Type E |

| Manufacturing Process: | Casting |

| Material: | Iron |

| Surface Treatment: | Sand Blasting |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What maintenance practices should be followed to keep gym pulley systems in optimal condition?

To keep gym pulley systems in optimal condition, the following maintenance practices should be followed:

1. Regular Inspection:

Perform regular inspections of the pulley system to identify any signs of wear, damage, or misalignment. Check the cables, pulleys, and attachment points for any fraying, kinks, or corrosion. Ensure that the pulley wheels are rotating smoothly and that the cables are properly seated in their grooves.

2. Cleaning:

Regularly clean the pulley system to remove dirt, dust, and debris that can accumulate over time. Use a mild detergent or gym equipment cleaner to wipe down the cables, pulleys, and attachment points. Avoid using harsh chemicals that may damage the materials or coatings of the pulley system.

3. Lubrication:

Apply a suitable lubricant to the pulley system as recommended by the manufacturer. Lubrication helps reduce friction, ensuring smooth operation and prolonging the lifespan of the cables and pulleys. Follow the manufacturer’s instructions on the type of lubricant to use and the frequency of application.

4. Cable Tension:

Check and adjust the cable tension regularly. Over time, cables may stretch or loosen, affecting the performance and resistance of the pulley system. Consult the equipment manual or seek professional assistance to ensure proper cable tension according to the manufacturer’s guidelines.

5. Weight Stack Alignment:

If the gym pulley system uses a weight stack, ensure that the weight plates are properly aligned and seated on the guide rods. Misaligned weight plates can cause uneven resistance or interfere with the smooth movement of the cables. Make any necessary adjustments to maintain proper weight stack alignment.

6. Replace Worn Components:

Regularly inspect the cables, pulleys, and other components for signs of wear or damage. If any components show significant wear, such as frayed cables, cracked pulleys, or worn attachment points, replace them promptly with compatible parts from the manufacturer. Using worn components can compromise the safety and performance of the pulley system.

7. Calibration:

If applicable, periodically calibrate the pulley system to ensure accurate resistance levels. Follow the manufacturer’s instructions or consult a professional technician to calibrate the pulley system properly. Calibration helps maintain consistency and reliability in the resistance provided by the pulley system.

By following these maintenance practices, gym owners and users can keep the pulley systems in optimal condition, ensuring smooth operation, safety, and longevity of the equipment.

Can gym pulleys be upgraded or customized to suit specific workout preferences?

Yes, gym pulleys can often be upgraded or customized to suit specific workout preferences. Here are some ways in which gym pulleys can be modified:

1. Attachment Options:

Gym pulleys often come with various attachment options, such as bars, ropes, handles, or straps. These attachments can be interchanged or upgraded to provide different grip variations or target specific muscle groups. For example, you can replace a standard straight bar with an angled bar or a rope attachment for different exercises.

2. Additional Pulley Stations:

Some gym pulley systems allow for the addition of extra pulley stations. This enables multiple users to train simultaneously or provides more exercise options by attaching different accessories to each station. Additional pulley stations can expand the versatility and functionality of the pulley system.

3. Adjustable Pulley Heights:

Certain gym pulley machines have adjustable pulley heights. This feature allows users to change the position of the pulleys to accommodate various exercises and body sizes. Adjusting the pulley heights can optimize the range of motion and exercise effectiveness.

4. Weight Stack Upgrades:

In some cases, gym pulley systems have removable weight stacks that can be upgraded or customized. This allows for the addition of more weight plates to increase the maximum resistance. Upgrading the weight stack provides greater challenge and accommodates the strength progression of the user.

5. Cable Length Adjustments:

Depending on the pulley system, the cables may have adjustable lengths. This feature allows users to modify the cable length to suit their height or exercise requirements. Adjusting the cable length ensures proper form and range of motion during exercises.

6. Resistance Modifications:

While some gym pulleys use weight stacks for resistance, others may use plate-loaded systems or resistance bands. These resistance options can often be modified or customized to adjust the level of resistance. For example, adding or removing weight plates or using different tension bands can alter the resistance levels.

7. Personalized Accessories:

Various accessories and add-ons are available for gym pulleys, allowing users to personalize their workouts. Examples include ankle cuffs, tricep ropes, ab straps, and specialized handles. These accessories can enhance exercise variety and target specific muscle groups.

It’s important to note that the extent of customization or upgradability may vary depending on the specific gym pulley system. Some systems may offer more flexibility for modifications, while others may have limited options. It’s advisable to consult the manufacturer’s instructions or contact customer support to inquire about the upgrade or customization possibilities for a particular pulley system.

By exploring the available options for attachment upgrades, additional pulley stations, adjustable pulley heights, weight stack upgrades, cable length adjustments, resistance modifications, and personalized accessories, individuals can customize their gym pulleys to suit their specific workout preferences and goals.

What types of materials are typically used in the construction of gym pulleys?

Gym pulleys are constructed using a variety of materials that are chosen for their durability, strength, and smooth operation. Here are some commonly used materials in the construction of gym pulleys:

1. Metal:

Metal, such as steel or aluminum, is frequently used in the construction of gym pulleys. These metals offer excellent strength and durability, making them suitable for handling heavy loads and providing long-lasting performance. Steel is known for its robustness, while aluminum is valued for its lightweight nature.

2. Nylon:

Nylon is a popular material for gym pulley wheels or sheaves. It is chosen for its low friction properties, which allow for smooth and quiet operation. Nylon pulleys are resistant to wear and can withstand repetitive use without compromising performance. They are also lightweight and cost-effective.

3. UHMW (Ultra-High-Molecular-Weight Polyethylene):

UHMW polyethylene is a high-performance plastic material commonly used in gym pulleys. It has excellent strength, low friction coefficient, and high wear resistance. UHMW pulleys provide smooth rotation, reduce noise, and require minimal maintenance. They are also resistant to chemicals and impact, making them suitable for demanding gym environments.

4. Stainless Steel:

Stainless steel is utilized in gym pulleys for its corrosion resistance and durability. It is commonly used in pulley shafts, brackets, and other components that require high strength and resistance to moisture or sweat. Stainless steel pulleys maintain their performance and appearance over time, even in humid or corrosive environments.

5. Plastic Composites:

Plastic composites, such as reinforced polymers or fiberglass-reinforced plastics, are sometimes used in the construction of gym pulleys. These materials offer a balance between strength, weight, and cost. Plastic composite pulleys can provide durability and smooth operation while being lighter and more affordable compared to all-metal alternatives.

6. Bearings and Bushings:

In addition to the materials mentioned above, gym pulleys incorporate bearings or bushings to facilitate smooth rotation. Bearings, typically made of steel or ceramic, minimize friction and allow the pulleys to rotate freely. Bushings, often made of bronze or other self-lubricating materials, provide low-friction contact points for the rotating components.

It’s important to note that the specific materials used in gym pulleys can vary depending on the manufacturer, design, and intended use of the equipment. Manufacturers may employ a combination of materials to optimize performance, durability, and cost-effectiveness.

In summary, gym pulleys are commonly constructed using materials such as metal (steel or aluminum), nylon, UHMW polyethylene, stainless steel, plastic composites, as well as bearings and bushings. These materials offer a balance of strength, durability, low friction, and corrosion resistance, ensuring smooth operation and longevity of the gym pulley systems.

editor by CX

2024-05-03