Product Description

Production description

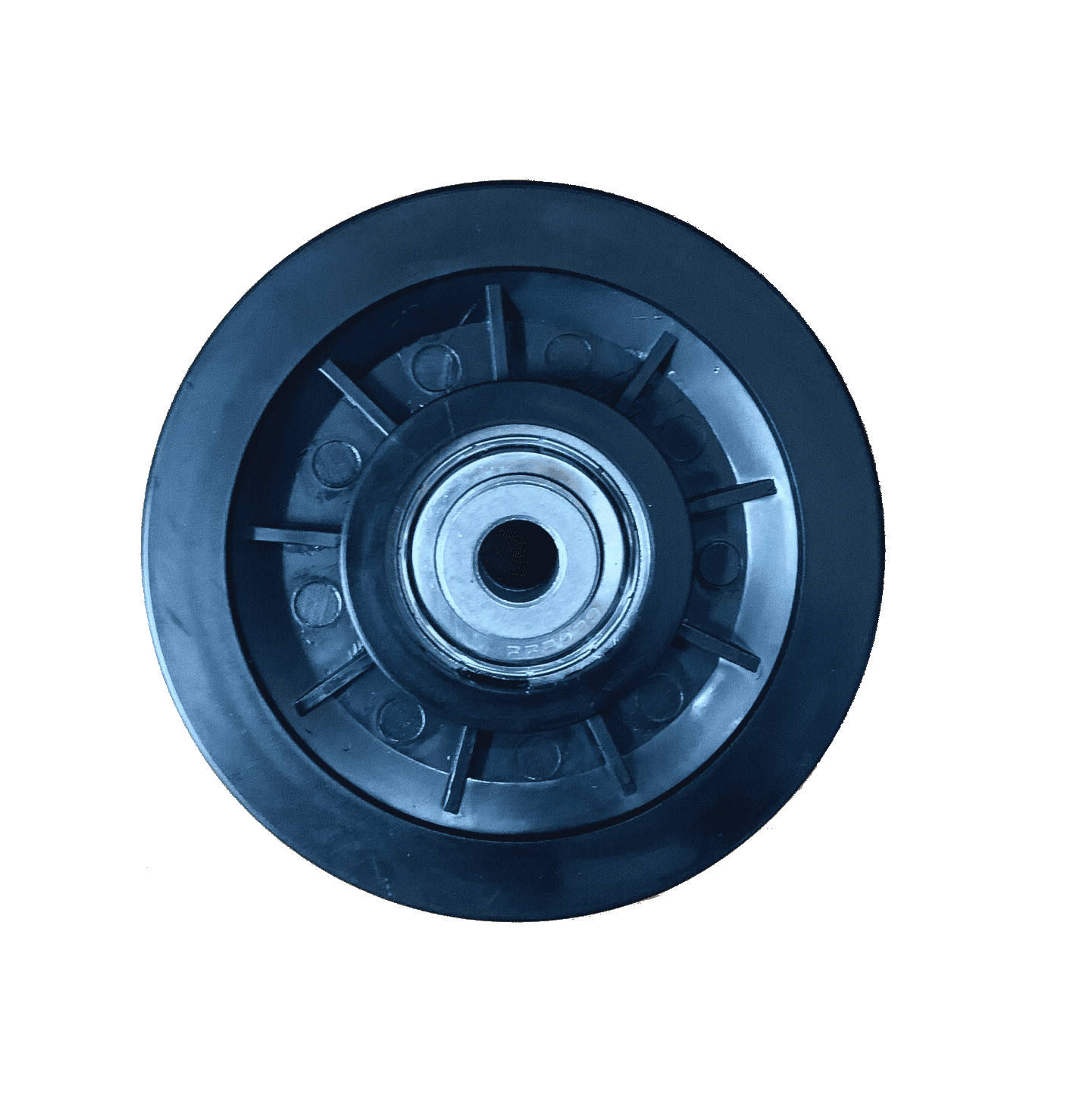

Outdoor Power New Parts Idler Idler Pulley Replaces

- ID: 3/8″ | OD: 4 7/8″ | Height: 1-1/8″

- Compatible with MTD 38″, 42″, 46″ and 54″ Decks

- Compatible with Cub Cadet Parts: 756- 0571 9B, 756- 0571 9C, 956- 0571 9, and 956- 0571 9C

- Compatible with MTD Parts: 753-5711, 756- 0571 9B, 756- 0571 9C, 956- 0571 9, and 956- 0571 9C

Our advantages:Focus on the stamping/welding/bending of the metal parts for automotive and construction application more than 30 years.

Leading Equipment:welding robots ,continue gas stations,CNC machining centers,CNC pipe bending machines,laser cutting machine.

Inspection Equipments:CMM,Five Elemental Analyzers, Salt spray test machine,Tensile testing machine.

We now have 100 customers from all over the world.

1. We have own factory and 80% of staff in our company worked for more than 10 years.

2. We provide a competitive price.

3. High precision, tolerance can be within ±0.01mm.

4. 14 years’ export experience.

5. Small order also is welcomed.

6. We can also provide one-stop service, including mold and assembly.

7. NDA apply to all customers.

| Mold Material | DC01,DC04,DC06 |

| Tooling life Time | 100K times |

| Tooling Material | 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Surface Treatment | Anodized, powder coating, lacquer coating, black oxide |

| Salt and spy test | From 72-480 h |

| Size | 1) According to customers’ drawings 2) According to customers’ samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001:2015 & IATF 16949 |

| Payment Term | T/T, L/C, Trade Assurance |

New Project Product Development Process

According to APQP process develpment plan from TS 16949 Quality Management System.

Raw Material Warehouse

Prepare the raw material according to customer delivery schedule and carry out FIFO exactly by ERP system.

Raw Material Chemical Element

Mechanical PropertiesTest Before Production ,the first step of the quality control.

Stamping Workshop

Overview of the Stamping workshop with cover the

Stamping equipment from 100T to 800T.

Hydraulic Press cover from 50T to 3100T.

With the mold(die,tooling) produce by ourselves we can customize all kinds of metal shape according to customer drawing call out.

Bending Workshop

CNC bending machine with servo control precise control the tolerance according to customer requirement.

The capacity of bending diameter reach to Φ135mm.

Welding Workshop

Welding robot with Synchronous workstation introduce from CHINAMFG Japan ,we had 23pcs welding arm with 64 pcs working stations,sheild welding support by Continuous gas supply station.

Brazing Welding For Pipe

Pipe with brazing welding can get perfect out appearance also reduce leaking on welding area.

Spot Welding (Resistance welding)

The ABB resistance welding robot can improve the welding joint strength also Improve spot welding efficiency.Reduce defects of traditional spot welding.

Surface Treatment

The coating line improves the efficiency, reduces the pollution to the environment, and the wastewater discharge after industrial treatment reaches the national standard.

Mold Workshop Warehouse

We can design and manufacture molds according to customer requirements,2500 square meter special for stamping mold warehouse.

Tooling Prepare

We simulated the workpiece by J-STAMPING software ,then we design the mold for metal sheet part ,not only it short the leadtime for development but also saving the cost for customer.

Gantry CNC machining center

The capacity of the CNC machining center can reach 3200*2500*1000mm,the tolerance can reach 0.008mm after test by CMM and Handy scHangZhou equipment.

Dimension Inspection

The mold and inspect gauge also the PPAP part was inspect by the CMM and Handy scHangZhou equipment.

ERP System In Our Company

All data support by ERP System, Cover From Raw Material Incoming To Shipment.

Customer Audit

* Evaluate the quality of customer service.

* Compare the quality with previously established goals.

* Identify gaps for improvement.

* Find ways to improve customer service.

* Gather all of the required data with Live Agent.

* Check activities.

Company Team

Team Working Together For Bright Future

ENJOY THE WORK, ENJOY THE LIFE.

Cooperative Partner

Thanks To Ford, CHINAMFG Moters, Toyota,CAMSD,FAW-VOLKSWAGEN, HONDA,JMC.

FAQ:

| 1. Do you provide samples? is it free or extra? |

| Yes, we can offer the sample for free charge but do not pay the cost of freight. |

| 2. How about the shipping cost? |

| The cost of shipping depends on the method you choose to obtain the goods. Express delivery is usually the fastest method, but it is also the most expensive method. Shipping is the best solution for large quantities. For the exact shipping cost, we can only provide you with detailed information after knowing the quantity, weight and dimension. |

| 3. Do you have Stock productions to sell? |

| Yes, of course. But we also offer OEM service. The mold is customized, Please send us some drawing. What information do you want to know if i want to get a quotation? a). The application for your products. b). Special package methods if you needs. |

| 4. Do you inspect the finished products? |

| Yes. Each step of products will be carried out inspection by QC department until shipping |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type C |

| Manufacturing Process: | Forming |

| Samples: |

US$ 32.5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there different types of gym pulleys, and how do they vary in fitness equipment?

Yes, there are different types of gym pulleys that vary in fitness equipment. Here’s an overview of the common types of gym pulleys and their variations:

1. Fixed Pulleys:

Fixed pulleys are stationary pulleys that are mounted to a fixed point or structure. They have a simple design with a grooved wheel that rotates on a fixed axle. Fixed pulleys change the direction of force, allowing users to pull or lift weights in a different direction. They are commonly used in cable machines and provide a consistent resistance throughout the exercise movement.

2. Adjustable Pulleys:

Adjustable pulleys are designed to change the height or position of the pulley attachment point. They typically feature a sliding mechanism or multiple attachment points along a vertical or horizontal track. By adjusting the attachment point, users can modify the mechanical advantage and resistance experienced during exercises. Adjustable pulleys offer versatility and allow for a wide range of exercise variations.

3. Cable Crossover Machines:

Cable crossover machines incorporate a combination of pulleys and cables to create a versatile and comprehensive workout station. These machines feature two or more pulley systems positioned on opposite ends, allowing users to perform various exercises targeting different muscle groups. Cable crossover machines often have adjustable pulleys, enabling users to customize the resistance and exercise angles.

4. Functional Trainers:

Functional trainers are multi-purpose fitness equipment that utilize pulley systems. They typically consist of two independent weight stacks and pulley systems on each side. Functional trainers offer a wide range of exercise possibilities, including traditional strength training exercises, functional movements, and rehabilitation exercises. The pulley systems in functional trainers are adjustable and allow users to target specific muscle groups from different angles.

5. Selectorized Machines:

Selectorized machines are weight-based fitness equipment that incorporate pulley systems. These machines feature a stack of weight plates with a selector pin that allows users to choose the desired weight. The weight stack is connected to a pulley system, enabling users to perform various exercises while adjusting the resistance level easily. Selectorized machines often have multiple pulleys and cable attachment points to provide exercise versatility.

6. Smith Machines:

Smith machines are a type of weightlifting equipment that include a barbell attached to a guided vertical track. The barbell moves along the track with the help of pulleys, allowing for controlled and safer weightlifting exercises. Smith machines often incorporate pulley systems for additional cable-based exercises, providing more workout options.

In summary, gym pulleys vary in fitness equipment and include fixed pulleys, adjustable pulleys, cable crossover machines, functional trainers, selectorized machines, and pulley systems in Smith machines. Each type of pulley offers specific features and functionality, providing users with different exercise options and resistance variations.

What safety considerations should be kept in mind when using gym pulley machines?

When using gym pulley machines, it’s important to prioritize safety to prevent injuries and ensure a safe workout environment. Here are some key safety considerations to keep in mind:

1. Proper Technique and Form:

Learn and practice proper technique and form for each exercise. Incorrect form can increase the risk of injury. If you’re unsure about the correct technique, seek guidance from a qualified fitness professional or trainer.

2. Warm-Up and Cool-Down:

Always warm up before starting your workout session. A proper warm-up prepares your muscles and joints for exercise, reducing the risk of strains or sprains. Similarly, cool down and stretch after your workout to promote recovery and flexibility.

3. Use Appropriate Resistance:

Select an appropriate resistance level that matches your fitness level and goals. Starting with excessive resistance can lead to poor form and potential injuries. Gradually increase the resistance as your strength improves.

4. Adjust the Equipment:

Ensure that the pulley machine is properly adjusted to your body size and range of motion. Adjust the seat height, cable attachment points, and handles to maintain proper alignment and comfortable positioning during exercises.

5. Maintain Control and Stability:

Always maintain control and stability during exercises. Avoid sudden jerky movements or swinging motions that can strain your muscles or cause accidents. Focus on smooth, controlled movements throughout the entire range of motion.

6. Use Safety Features:

Make use of any safety features provided with the pulley machine. These may include safety pins, weight stack locks, or emergency stop buttons. Familiarize yourself with these features and use them appropriately to ensure safe operation.

7. Wear Appropriate Attire:

Wear proper workout attire, including comfortable clothing and athletic shoes with good support. Avoid loose clothing or dangling accessories that can get caught in the pulley system.

8. Stay Hydrated:

Stay hydrated throughout your workout session. Proper hydration is essential for optimal performance and helps prevent muscle cramps or fatigue.

9. Listen to Your Body:

Pay attention to your body’s signals during exercise. If you experience pain, dizziness, or excessive fatigue, stop the exercise and seek medical attention if needed. Pushing through pain or discomfort can lead to injuries.

10. Maintain Equipment:

Regularly inspect the pulley machine for any signs of wear, damage, or malfunction. If you notice any issues, report them to the appropriate personnel or facility management. Follow the manufacturer’s guidelines for equipment maintenance and cleaning.

By following these safety considerations, you can minimize the risk of injuries and create a safe workout environment when using gym pulley machines.

What types of materials are typically used in the construction of gym pulleys?

Gym pulleys are constructed using a variety of materials that are chosen for their durability, strength, and smooth operation. Here are some commonly used materials in the construction of gym pulleys:

1. Metal:

Metal, such as steel or aluminum, is frequently used in the construction of gym pulleys. These metals offer excellent strength and durability, making them suitable for handling heavy loads and providing long-lasting performance. Steel is known for its robustness, while aluminum is valued for its lightweight nature.

2. Nylon:

Nylon is a popular material for gym pulley wheels or sheaves. It is chosen for its low friction properties, which allow for smooth and quiet operation. Nylon pulleys are resistant to wear and can withstand repetitive use without compromising performance. They are also lightweight and cost-effective.

3. UHMW (Ultra-High-Molecular-Weight Polyethylene):

UHMW polyethylene is a high-performance plastic material commonly used in gym pulleys. It has excellent strength, low friction coefficient, and high wear resistance. UHMW pulleys provide smooth rotation, reduce noise, and require minimal maintenance. They are also resistant to chemicals and impact, making them suitable for demanding gym environments.

4. Stainless Steel:

Stainless steel is utilized in gym pulleys for its corrosion resistance and durability. It is commonly used in pulley shafts, brackets, and other components that require high strength and resistance to moisture or sweat. Stainless steel pulleys maintain their performance and appearance over time, even in humid or corrosive environments.

5. Plastic Composites:

Plastic composites, such as reinforced polymers or fiberglass-reinforced plastics, are sometimes used in the construction of gym pulleys. These materials offer a balance between strength, weight, and cost. Plastic composite pulleys can provide durability and smooth operation while being lighter and more affordable compared to all-metal alternatives.

6. Bearings and Bushings:

In addition to the materials mentioned above, gym pulleys incorporate bearings or bushings to facilitate smooth rotation. Bearings, typically made of steel or ceramic, minimize friction and allow the pulleys to rotate freely. Bushings, often made of bronze or other self-lubricating materials, provide low-friction contact points for the rotating components.

It’s important to note that the specific materials used in gym pulleys can vary depending on the manufacturer, design, and intended use of the equipment. Manufacturers may employ a combination of materials to optimize performance, durability, and cost-effectiveness.

In summary, gym pulleys are commonly constructed using materials such as metal (steel or aluminum), nylon, UHMW polyethylene, stainless steel, plastic composites, as well as bearings and bushings. These materials offer a balance of strength, durability, low friction, and corrosion resistance, ensuring smooth operation and longevity of the gym pulley systems.

editor by CX

2024-05-14